Umshini Wokugcwalisa Amashubhu we-plasticlaminate ne-aluminium tube (kufika ku-320 ppm)

IMINININGWANE YOMKHIQIZO

Incazelo emfushane yomshini wokuvala amashubhu epulasitiki

1. Iumshini wokuvala amashubhu epulasitikiisebenzisa isikrini sokuthinta se-Siemens 10-intshi kanye nesofthiwe yokulawula ye-Japanese Keyence PLC-KV8000.

2. Ithubhu ye-filler control system yokusebenza kwe-servo kanye ne-logic yokulawula ukunyakaza

3. Umsebenzi wokulawula: Ngemva kokukhishwa kweshubhu noma ukuphuma, kusekhona ishubhu elihlala eketango lamapayipi - ukuvala shaqa

4. Umsebenzi wokuphepha (isitobhi esiphuthumayo kanye neswishi yokuvikela) yonke iminyango ikhiyiwe uma ishubhu yesigcwalisi isebenza.

5. umshini wokugcwalisa ishubhu othomathikhiinawo Wonke amadivaysi e-alamu achaziwe angalungiswa ngephaneli yokulawula

6. I-servo kagesi ye-tube ye-filler ingalungisa isivinini ngabanye, futhi isivinini sokukhiqiza somshini wonke singashintshwa.

7. Idivayisi ye-inches isebenza ngesivinini esiphansi

8. Iphaneli enkulu ukulungisa zonke izilungiselelo zokukhiqiza

9. Iphaneli yokusebenza ibonisa inani lokukhiqiza kanye nesimo somugqa wokukhiqiza

10. Ngokwezidingo zekhasimende, setha amasethi amaningi amafomula e-tube of filler

11. Iumshini wokugcwalisa ishubhu othomathikhiiphaneli yokulawula ingasetha imisebenzi yepharamitha

12. Umshini wokugcwalisa i-tube othomathikhi unephaneli yokusebenza evikelwe amazinga we-3 ahlukene wokusebenza.

13. Ikhabethe likagesi elizimele lensimbi engagqwali elinesimo somoya, izinga lokuvikela lifinyelela ku-IP65 noma ngaphezulu.Amathreyi ekhebula phakathi kwamakhabethe kagesi nemishini asebenzisa amathreyi ekhebula avaliwe, futhi izintambo zingena zisuka phezulu emshinini ezingeni eliphezulu.

Ngokuzayo, isistimu yokulawula ingasebenzisa i-Siemens profitnet ukudlulisa idatha ku-MES futhi ixhume nohlelo lwe-MES.

Umshini Wokugcwalisa Amashubhu we-plasticlaminate ne-aluminium tube

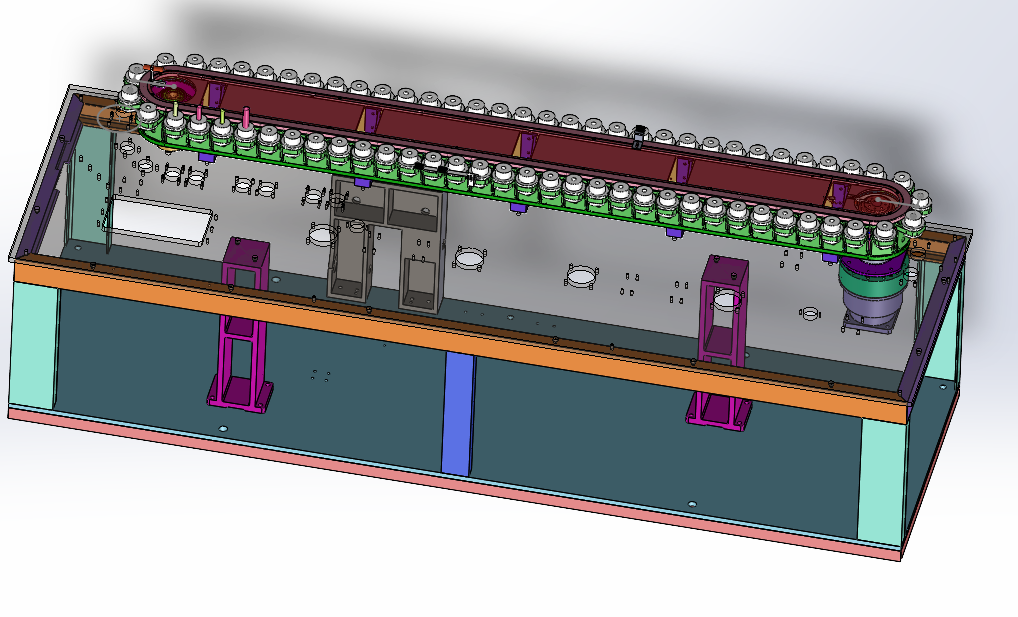

I-LFC4002Umshini Wokugcwalisa Amashubhuiyisiteshi sokugcwalisa kanye nokuvala umshini wokuvala ishubhu wepulasitiki ogcwele we-servo owenziwe ngokuzimela, oklanywe futhi owenziwe yinkampani yethu.Ifanele ukugcwalisa ukucaciswa okuhlukahlukene kwamashubhu enziwe yi-aluminium-plastiki eyinyumba eyinyumba noma engeyona inzalo, amashubhu epulasitiki namashubhu e-aluminium.Isivinini sokuklama singamashubhu angama-360/umzuzu, kanti isivinini esivamile sokukhiqiza esiphezulu seshubhu yokugcwalisa singamashubhu angama-250-340/ngomzuzu.Ukunemba kokugcwalisa kungu-≤±0.5%.Ipayipi le-aluminium livalwa ngokuvala ukugoqa, ipayipi eliyinhlanganisela ye-aluminium-plastic livalwa ngomoya oshisayo noma ukufudumeza kwe-high-frequency, kanti ipayipi lepulasitiki livalwa ngokuvaleka kwangaphakathi ukushisisa komoya oshisayo.

Umshini Wokugcwalisa Amashubhu Indlela yokudlulisa enkulu:

Umshini wokugcwalisa ishubhu othomathikhiyamukela umzila wesitimela obalulekile wensimbi ye-alloy, i-anti-vibration enamashubhu amathathu okukhiya inkomishi yomshini wokukhiya, kanye nesethi yeketango le-4kW servo eliqhutshwa izikhawu leketango lokuhambisa indebe.Umshini wokuvala amashubhu epulasitiki unquma isivinini esikhulu nokuzinza kwemishini yokupakisha.

Umshini Wokugcwalisa Amashubhu we-tube cup chain odlulisa umshini wokudlulisa uqukethe ama-rail angumhlahlandlela wensimbi wensimbi onemigodi emithathu engaphezulu, ephansi kanye naseceleni.Ama-bearings amathathu aginqikayo afakwe esihlalweni senkomishi yeshubhu, futhi ama-rolling bearings ahamba ngendlela emiseleni bese eshayela ipayipi.Iketango lenkomishi yeshubhu aligugi.Kukhona futhi ama-roller enaliti amabili angaphezulu nangaphansi afakwe ezikhonkwaneni ukuze azungeziswe.

umshini wokuvala amashubhu epulasitiki Iketango le-hose conveyor liheha futhi lilungise izihlalo zamashubhu (ukuma okunezinhlamvu ezintathu, isitimela sensimbi) ukuya kwelinye ngebhande lokuhambisa elinamazinyo.Ibhande lokuhambisa elinamazinyo lihamba ngokuqinile ngokuya nge-transmission trajectory yesondo lokushayela.Inkomishi yeshubhu ifakwe iringi ngayinye yokuhlala.Inkomishi yeshubhu yenziwe ngezinto ze-POM futhi ihlangabezana nokucaciswa kwepayipi kanye nezidingo zokuklama.

Ukuvikela ukulayisha ngokweqile komshini wokugcwalisa umshini wamashubhu kwenziwa ngokunemba kokubuya kwe-torque ehambisanayo efakwe esondweni lokudlulisa, elinempilo ende yesevisi.Uma uchungechunge lwamapayipi lubhajwe, i-clutch iyanqanyulwa, iswishi yokusondela iyaqaliswa, futhi umshini uyama ngokushesha..

Umshini Wokugcwalisa Amashubhu Inqubo yokuhlanza ku-inthanethi

1. Umshini wokuvala amashubhu epulasitikiuhlelo lokugcwalisa kanye ne-hopper ingahlanzwa ngokuzenzakalelayo yisiteshi se-CIP ku-loop evaliwe ngesikhathi esifanayo.

2. Ngaphambi kokuqala i-CIP, i-nozzle yokugcwalisa ifakwe ne-CIP dummy cup ethize, futhi uketshezi lokuhlanza luzokhishwa emshinini wokugcwalisa ngepayipi elixhunywe ku-CIP dummy cup.

3. Indawo yokusebenzela ye-CIP (ehlinzekwa yikhasimende) ihlinzeka nge-ejenti yokuhlanza emnyango we-hopper.Ibhola le-spray lifakwe kusilinda, futhi ibhola le-spray lifafaza i-ejenti yokuhlanza endaweni engaphakathi yesilinda.Uhlelo lokugcwalisa umshini wokugcwalisa amashubhu epulasitiki luklanyelwe ngokwezimiso zokuhlanzeka, futhi uketshezi lokuhlanza lwe-CIP lungafinyelela kuzo zonke izindawo, amapayipi nezinsimbi ezihlangana nomkhiqizo ngesikhathi senqubo yokukhiqiza.Izingxenye ezihambayo ezihlangana nomkhiqizo ngesikhathi sokukhiqiza, njengamaphampu e-piston, ama-agitators, njll., zizophinde zijikeleze ngokufanele ngesikhathi sokuhlanza i-CIP ukuze kuqinisekiswe ukuthi zonke izindawo zezingxenye ezihambayo zingahlanzwa ngokugcwele.

4. Ipayipi elixhumayo loketshezi lokuhlanza ukuze libuyele ohlelweni lwe-CIP yekhasimende (iphampu yokubuyisela ayifakiwe kububanzi bokunikezwayo)

5. Sungula imijikelezo yokuhlanza nokubulala amagciwane ngokwezidingo zamakhasimende, futhi konke ukuhlanza nokubulala amagciwane kulungiselelwe esiteshini se-CIP.

6. Amapharamitha afana nokushisa, ingcindezi, izinga lokugeleza kanye nesikhathi somjikelezo we-CIP angasethwa esiteshini se-CIP ngokuvumelana nezidingo zamakhasimende.

7. I-nozzle yokugcwalisa yomshini wokuvala amashubhu epulasitiki ingaphinde ikhishwe ngokushesha ohlelweni lwepompo ukuze ihlanzwe ungaxhunyiwe ku-inthanethi.

Ithrafikhi ye-8.CIP idinga u-2T/H noma ngaphezulu

Umshini Wokugcwalisa Amashubhu osebenzisa amarobhothi ukuphakela amashubhu (amashubhu angu-15x2 athathwa ngemigqa ephindwe kabili isikhathi ngasinye, izikhathi ezingu-9-12/ngomzuzu):

Ngokohlelo oluhleliwe, irobhothi likhipha imigqa emibili yamapayipi epayipini elingashintshiwe isikhathi ngasinye, liwadlulisele phezulu enkomishini yeshubhu, bese liwafaka zibheke phezulu enkomishini yeshubhu.Irobhothi lisebenzisa indlela yokusekela ishubhu, futhi lisebenzisa insimbi engagqwali ukuze liqinise iminwe.Kwenziwe, ingahlakazwa ukuze kuhlanzwe futhi kubulawe amagciwane noma kubulawe amagciwane ngesifutho se-hydrogen peroxide

I-grating ithola ukuthi kukhona yini i-tubeleft emunweni werobhothi engakafakwa enkomishini yeshubhu, bese ivula indlela yokukhipha ukuze ikhiphe ipayipi emunweni, bese iqhubeka nokuthatha ishubhu.

Umshini Wokugcwalisa Amashubhu we-LFC4002 unezinzuzo ezilandelayo:

a.Uhlelo lokulawula: I-tube yokugcwalisa ithatha isikrini sokuthinta se-Siemens kanye nesilawuli sokunyakaza se-Keyence saseJapane, ibhasi eliqhutshwa ngokugcwele le-servo;umsindo ungaphansi kwama-decibel angu-75.

b.Indlela yokwenza inkomba: i-tube yokugcwalisa isebenzisa isistimu ye-servo njenge-indexer, futhi ithuthukisa isofthiwe ehlukile ukuze kwandiswe isilinganiso esiguqukayo kuya ku-static, yandise isikhathi esimile sokugcwalisa nokubeka uphawu, futhi iqinisekise ukuthi isivinini esizinzile sezinto zokusebenza singaphezu kuka-260pcs/min.

c.Umzila wesitimela we-Cups chain guide: Umshini ozenzakalelayo wokugcwalisa amashubhu usebenzisa ukusebenza kweziteshi ezine, i-alloy iron integral guide rail, kanye nendlela yokukhiya yesibambi senkomishi ye-tube ene-auto-bearing three.

d.Ukuhlukaniswa kwezindawo: i-hose yokuzihlanza, ukulayishwa kweshubhu ye-robot, ukulayishwa kwe-servo flap tube, ukulayishwa kweshubhu okuzenzakalelayo, ukugcwalisa nokuvala uphawu, ukukhishwa kwe-servo tube nezinye izindawo zihlukaniswa ngokuvumelana nezidingo ze-GMP.

e.Ukuma kwebhokisi lamapayipi: Umshini wokugcwalisa ishubhu othomathikhi wamukela izinto zokuhamba ezinezingqimba ezimbili.Ibhokisi le-hose lihanjiswa kungqimba olungaphezulu, libekwe endaweni yesikhulumi esithambekele, futhi ibhokisi elingenalutho libuyiselwa kungqimba olungezansi.

f.Indlela yokulayisha ishubhu: Umshini wokulayisha werobhothi noma weshubhu ungena kumashubhu, futhi ungagcina amashubhu angama-3000-4000.

h.I-Servo benchmarking: isignali yokuthwebula umbala wombala ogulayo, ukuma kwe-torque enkulu ye-servo, isivinini esikhulu nokuzinza.

i.Ukugcwaliswa kwe-Servo: Umshini wokugcwalisa ishubhu ozenzakalelayo wamukela i-servo drive yomugqa ogcwele kanye nokugcwaliswa kwepompo ye-ceramic egcwele, engasoze yaguga.

j.Ukugoqa kanye nokwenza isicaba kwepayipi le-aluminium: Indlela yokubopha kanye nokwenza isicaba yedivayisi yokuvala umsila ekuqaleni yayiwuhlobo lwesikelo, olungacindezela umoya kalula eshubhuni.Manje isishintshelwa ekubeni i-clamping evundlile kanye nendlela yokubeka isicaba, engenalo uthuli futhi egwema ukushayela igesi epayipini.

k.Ukuvala umsila weshubhu le-Aluminum: Lapho uvala umsila, ukugoqa nokubopha kusebenzisa ukunyakaza komugqa ovundlile oqondiswa yi-bearing-guide (ekuqaleni uhlobo lokuthatha i-arc) ngaphandle kokudonsa ishubhu liye phezulu.Lokhu kulungele ikakhulukazi imisila ephindwe kathathu.

n.Idivayisi yokushajwa: I-servo ikhipha ipayipi elinezindlela ezine futhi inomsebenzi wokulahla.

o.Ukudlulisa okuhambisanayo: ukunyakaza okuphakathi kwe-servo, ukudlulisa umkhombe ohlukile, ukuvumelanisa okuhle.

p.I-pressure hopper: yamukela imodi yokuvula ngokushesha yepayipi yokusabalalisa ukuze ixhume kupompo yokugcwalisa.

q.I-CIP eku-inthanethi: Ingahlanzwa ku-inthanethi noma ungaxhunyiwe ku-inthanethi.

Ipharamitha yobuchwepheshe

- Umshini Wokugcwalisa Amashubhu Imishini eyinhloko yemingcele yezobuchwepheshe

| No | ipharamitha | amazwi | |

| Ukucaciswa kweshubhu (mm) | Ububanzi 13~30, ubude 60~250 |

| |

| Ukuma kombala (mm) | ±1.0 |

| |

| Umthamo wokugcwalisa (ml) | 1.5~200(Hlangana nokucaciswa kwe-5g-50g, imininingwane ethile namasayizi ngokuya ngezinhlobonhlobo nobuchwepheshe) |

| |

| Ukugcwalisa ukunemba (%) | ≤±0.5 |

| |

| Ukuvala imisila | Ukugoqa okuphindwe kabili, okuphindwe kathathu, nokumise okwesihlalo sehhashi kuyatholakala. |

| |

| Umthamo wokukhipha PPm | 250-300 |

| |

| Ishubhu efanelekayo | Ipayipi le-aluminium Ipayipi lepulasitiki Ipayipi lepulasitiki le-aluminium |

| |

| Ukusetshenziswa kwamandla (kW) | i-tube yokugcwalisa | 35 |

|

| Irobhothi | 10 |

| |

| Amandla | 380V 50Hz |

| |

| umfutho womoya | 0.6MPa |

| |

| Ukusetshenziswa komoya (m3/h) | 20-30 |

| |

| Ifomu lochungechunge lokudlulisela | (Kungeniswe kusuka e-Italy) Uhlobo lwebhande le-Rebar (i-servo drive) |

| |

| indlela yokudlulisela | I-servo drive ephelele |

| |

| usayizi (mm) | Ubude 3700 Ububanzi 2000 Ukuphakama 2500 |

| |

| Isamba sesisindo (kg) | 3500 | ||

I-Smart zhitong inabaklami abaningi abangochwepheshe, abangakwazi ukuklamaUmshini Wokugcwalisa Amashubhungokwezidingo zangempela zamakhasimende

Sicela usithinte ukuze uthole usizo lwamahhala @whatspp +8615800211936

Izigaba zemikhiqizo

-

I-imeyili

-

Ucingo

-

Phezulu

0086 15800211936

0086 15800211936